Why Surge Voltage Testing Is Important For Motors?

Surge voltage testing is used to discover insulation problems in wound materials. In studies, experts have determined that 60% of motor failures start out as coil shorts within a winding.

A surge voltage test is the only testing method that can determine insulation problems in wound materials between windings.

How does a surge test work?

During a surge test, a surge capacitor connected in parallel to the winding to be tested is discharged suddenly. A sinusoidal damped oscillation is created in the oscillating circuit created between the testing device and the winding, and this oscillation has a certain characteristic.

A surge test detects a fault between turns by observing a jump in the resonant frequency of this LC tank circuit. If the voltage produced by the surge is greater than the weakened dielectric strength of the turn insulation, one or more turns may be shorted out by arcing.

The surge comparison test finds shorts insulation weaknesses in coils, windings, electric motors, generators, alternators, and transformers. These faults are typically turn-to-turn, coil-to-coil, or phase -to -phase.

The surge test is the most efficient way to find turn insulation weaknesses. For those who manufacture or rewind motors, being able to manufacture coils free of insulation defects is paramount to reliability.

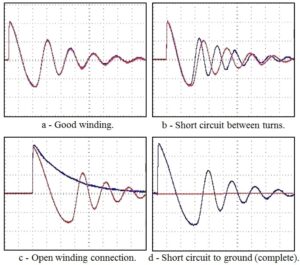

Surge Test Typical Waveform

Anyone can Identify from the above mention waveform that Motor Winding in which condition.