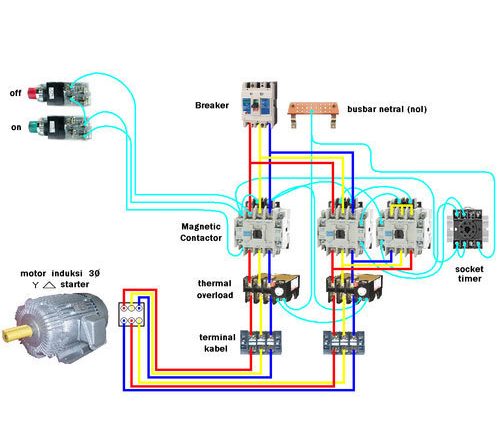

Why star delta starter required for a 3 phase induction motor with a higher rating?

Most induction motors are started directly on line, but when very large motors are started that way, they cause a disturbance of voltage on the supply lines due to the large starting current.

To limit the starting current surge, large induction motors are started at reduced voltage and then have full supply voltage reconnected when they run up to near rotating speed.

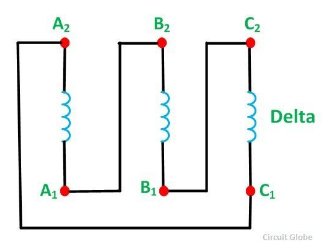

A star delta starter reduces the starting current by connecting the motor winding in Star at the time of starting. This reduces the voltage across the winding. The voltage across the winding will be( 1/Sqrt(3))*Line Voltage.

Image source: Circuit Globe

Working principle of star delta starter

This is the reduced voltage starting method. Voltage reduction during star-delta starting is achieved by physically reconfiguring the motor windings as illustrated in the figure below. During starting the motor windings are connected in a star configuration and this reduces the voltage across each winding.

This also reduces the torque by a factor of three. After a period of time, the winding is reconfigured as delta and the motor runs normally.

Star/Delta starters are probably the most common reduced voltage starters. They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply.