Construction and Working Principle of BLDC Motor

The construction and working principles of BLDC motors have many similarities to AC induction motors and brushed DC motors. Like all other motors, BLDC motors also have a rotor and a stator.

Electrical motors have been developed in various special types, such as stepper motors, servo motors, permanent magnet motors, etc. We have a lot of choices to choose a motor that is most suitable for our application.

A Brushless DC motor or BLDC motor is the type which is most suitable for applications that require high reliability, high efficiency, more torque per weight etc.

Construction Of A BLDC Motor

Just like any other electric motor, a BLDC motor also has a stator and a rotor.

Permanent magnets are mounted on the rotor of a BLDC motor, and stator is wound with a specific number of poles. This is the basic constructional difference between a brushless motor and a typical dc motor.

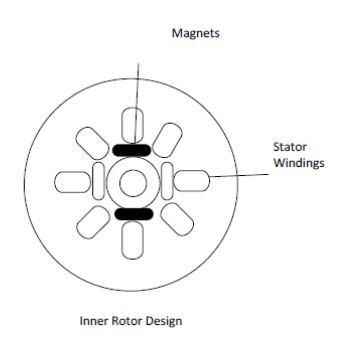

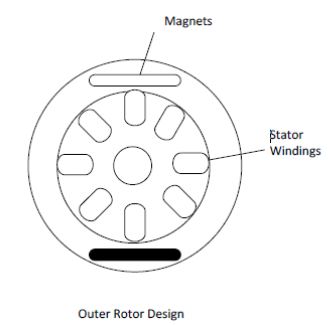

There can be two types of BLDC motor on the basis of construction :

1.BLDC Inner Rotor Design

This is a conventional design, where the rotor is located at the core (center) and stator winding surrounds it.

2. BLDC Outer Rotor Design

In this design, the rotor is external. i.e. stator windings are located at the core while the rotor, carrying permanent magnets, surrounds the stator.

Working Principle Of A BLDC Motor

Stator windings of a BLDC motor are connected to a control circuit (an integrated switching circuit). The control circuit energizes proper winding at proper time, in a pattern which rotates around the stator.

The rotor magnet tries to align with the energized electromagnet of the stator, and as soon as it aligns, the next electromagnet is energized. Thus the rotor keeps running.

Commutator helps in achieving unidirectional torque in a typical dc motor.

Obviously, commutator and brush arrangement is eliminated in a brushless dc motor. And an integrated inverter/switching circuit is used to achieve unidirectional torque.

That is why these motors are, sometimes, also referred as ‘electronically commutated motors’.

Brushless Vs. Brushed DC Motor

Brushes require frequent replacement due to mechanical wear, hence, a brushed DC motor requires periodic maintenance. Also, as brushes transfer current to the commutator, sparking occurs. Brushes limit the maximum speed and number of poles the armature can have. These all drawbacks are removed in a brushless DC motor. Electronic control circuit is required in a brushless DC motor for switching stator magnets to keep the motor running. This makes a BLDC motor potentially less rugged.

Benefits of BLDC motor over brushed motors

benefits of BLDC motor over brushed motors are listed below,

- Increased efficiency

- Reliability

- longer lifetime

- No sparking and less noise

- more torque per weight etc.